Spectacle Blinds

Spectacle Blinds Manufacturer

About the Product

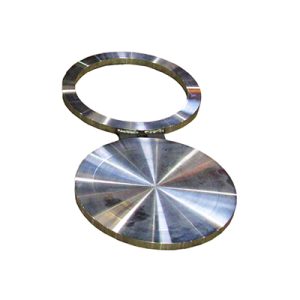

Spectacle Blinds are specialized piping components used for isolating sections of piping systems. They are designed to ensure a positive seal in the system, particularly during maintenance, inspections, or repairs. The name “Spectacle Blind” comes from its shape, which resembles a pair of spectacles, with one solid plate and one open plate connected by a small bridge. When the solid side is aligned with the pipe, the flow is completely blocked, and when the open side is aligned, normal flow resumes. These components are typically used in systems where regular isolation is required.

S Nomi is a prominent Spectacle Blinds Manufacturer in Kolkata, West Bengal and also for catering to the industrial needs of Odisha, Bihar, Chhattisgarh, Jharkhand, and Assam. Our company specializes in delivering high-quality Spectacle Blinds that offer robust and reliable solutions for piping systems in various industries. Known for their durability and precision, S Nomi’s Spectacle Blinds are manufactured to meet the specific requirements of numerous applications, ensuring the highest standards of safety and performance.

Manufacturing Details of the Product

S Nomi’s Spectacle Blinds are crafted from high-grade materials to ensure long-lasting performance and safety in various applications. Our manufacturing process includes:

- Material Selection: We use premium-quality carbon steel, stainless steel, and alloy steel, ensuring strength and durability even in high-pressure and high-temperature environments.

- Precision Machining: Our advanced CNC machines ensure precise dimensional accuracy for a perfect fit within the piping systems.

- Stringent Quality Control: Each spectacle blind undergoes rigorous testing and inspections to ensure that they meet international standards and are free from any defects or imperfections.

- Surface Treatment: Depending on the application, the spectacle blinds are treated with protective coatings, such as galvanization or epoxy, to prevent corrosion and extend the product’s lifespan.

Our state-of-the-art manufacturing facility ensures that we produce Spectacle Blinds that comply with ASME, ANSI, API, and other international standards.

Specifications of S Nomi Spectacle Blinds

- Material: Carbon steel, stainless steel (304, 316, 316L), alloy steel

- Size Range: ½ inch to 48 inches

- Pressure Class: Class 150 to Class 2500

- Standard Compliance: ASME B16.48, ANSI B16.5, API 590

- Thickness: As per standard or customized

- Face Type: Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- Surface Coating: Epoxy coating, galvanization, or paint for enhanced corrosion resistance

Application of Spectacle Blinds

Spectacle blinds are widely used in industries where it is necessary to temporarily or permanently isolate parts of a piping system. Common applications include:

- Oil & Gas Industry

- Petrochemical and Chemical Plants

- Power Generation

- Water Treatment Plants

- Steam Systems

- Pharmaceutical Industry

- Marine Industry

Spectacle Blinds are often installed in locations where regular maintenance or inspection is needed. They are especially useful in systems dealing with hazardous or high-pressure substances.

Technical Features of S Nomi Spectacle Blinds

- Complete Isolation: The solid plate provides total isolation of the piping system, making it ideal for maintenance or system inspection.

- Easy Installation and Removal: Designed for easy switching between open and closed positions, making them user-friendly and time-saving.

- High Corrosion Resistance: With a choice of materials such as stainless steel and protective coatings, our spectacle blinds offer excellent resistance to corrosion, ensuring longevity even in harsh environments.

- Versatile Sizes and Pressure Ratings: Available in a variety of sizes and pressure classes to suit the needs of different industries and applications.

- Compliance with International Standards: Manufactured to meet ASME, ANSI, and API specifications, ensuring that our products adhere to global quality standards.

- Custom Options: We provide customized options based on specific requirements, such as material type, size, and pressure rating.

What is a Spectacle Blind Used for?

Spectacle Blinds are primarily used for isolating sections of pipelines for inspection, maintenance, or repair. The solid plate blocks flow, ensuring that no fluid or gas passes through the system while work is being done. Once maintenance is complete, the open plate allows normal flow to resume.

These blinds are particularly useful in systems carrying hazardous materials where safety is critical, as they offer a visible and reliable method of ensuring complete isolation. Spectacle Blinds are often used in high-pressure systems, as they provide a secure and leak-proof seal. Their ease of use makes them ideal for industries that require frequent switching between open and closed positions in the piping system.

Why Choose S Nomi Spectacle Blinds?

As a trusted Spectacle Blinds Manufacturer in Odisha, Bihar, Chhattisgarh, Jharkhand, or Assam, S Nomi provides high-quality, precision-engineered blinds that are built to last. Our focus on quality, safety, and reliability ensures that our products meet the needs of demanding industrial applications. Whether you are located in Kolkata, West Bengal, Odisha, Bihar, Chhattisgarh, Jharkhand, or Assam, S Nomi is your go-to source for robust and efficient spectacle blinds that will enhance the performance and safety of your piping systems.

Products

- U Bolt Flange Manufacturer

- Jubilee Clamp Manufacturer

- Flexi Drop Manufacturer

- Hose Clip Manufacturer

- Flow Switch Manufacturer

- Rubber Diaphragm Valves Manufacturer

- MS Welding Rods Manufacturer

- Fastener Bullet Manufacturer

- Universal Clamp Manufacturer

- Hose Box Key Manufacturer

- Pressure Switch RT116 Manufacturer

- Heavy Flange Manufacturer

- Blind Plate Flange Manufacturer

- IS 6392 Type Flanges Manufacturer

- BS10 Plate Flanges Manufacturer

- EN 1092-1:2001 /TYPE O2/A Manufacturer

- API 6A Flanges Manufacturer

- Orifice Welding Neck Flanges Manufacturer

- Sprinkler Wall Flange Manufacturer

- SS Branch Pipe Manufacturer

- Fire Brigade 3 Way Flange Manufacturer

- Fire Brigade 4 Way Flange Manufacturer

- MS Angle Manufacturer

- MS Plate Manufacturer

- Hydrant Coupling Brass Manufacturer

- PU Connector Manufacturer

- Branch Pipe Brass Manufacturer

- EN 1092-1:2001 /TYPE 11/B1 Manufacturer

- Sprinkler Pendent Manufacturer

- Pipe Clamp Manufacturer

- Sprinkler Pipe Flexible Manufacturer

- Flexible Hose Manufacturer

- RRL Hose Manufacturer

- Sprinkler Upright Manufacturer

- Hose Box Knob Manufacturer

- Ring Type Joint Flanges Manufacturer

- Carbon Steel Flanges Manufacturer

- Alloy Steel Flange Manufacturer

- Weld Neck Flanges Manufacturer

- Threaded Flanges Manufacturer

- Spectacle Blinds Manufacturer

- Spades & Ring Spacers Manufacturer

- Slip on Flanges Manufacturer

- Screwed Flanges Manufacturer

- Dairy Fittings Manufacturer

- Reducing Flanges Manufacturer

- Orifice Flanges Manufacturer

- Long Weld Neck Flanges Manufacturer

- Lap Joint Flanges Manufacturer

- Plate Flange Manufacturer

- Forged Flange Manufacturer

- Flat Flanges Manufacturer

- Expander Flange Manufacturer

- Nut Bolt Flange Manufacturer

- AWWA Flanges Manufacturer

- EN 1092-1:2001 / TYPE O5/A Manufacturer

- ASME B 16.47 Series B WNRF Flanges Manufacturer

- ASME B 16.47 Series A WNRF Flanges Manufacturer

- EN 1092-1:2001 / TYPE 13/A Manufacturer

- Stainless Steel Flange Manufacturer

- Sprinkler Flange Manufacturer

- Pressure Flange Manufacturer

- Blind Flanges Manufacturer

- MS Flange Manufacturer

- High-Medium Flange Manufacturer

- Hydrant Coupling Flange Manufacturer

- Hose Box Flange Manufacturer

- GM Flange Manufacturer

- GI Flange Manufacturer

- Fire Brigade 3, 4 Way Flange Manufacturer